FAQ

Q1: What is the difference between Neutral Cure and Acetoxy (Acidic) Cure silicone?

A: The key difference is the byproduct released during curing and their applications:

Neutral Cure: Releases alcohol or oxime. Non-corrosive, making it safe for sensitive metals (copper, brass), stone (marble, granite), and substrates that could be etched by acid. Has little to no odor. Preferred for most construction and industrial applications.

Acetoxy Cure: Releases acetic acid (vinegar smell). Cures faster and is generally more cost-effective. Can corrode certain metals (copper, brass, untreated steel) and react with cementitious or alkaline materials. Best for glass, ceramics, and common plumbing (where corrosion is not a concern).

Q2: How long does it take to cure? Why does it feel dry on the surface but soft underneath?

A: Silicone cures by reacting with atmospheric moisture from the surface inward.

Skin-Over Time: 15-45 minutes (surface becomes touch-dry).

Cure Depth: ~3mm in 24 hours under standard conditions (23°C, 50% RH).

Full Cure: Can take 7-14 days for deep joints, depending on humidity, temperature, and joint depth. The soft core is normal during this period and will achieve full properties once fully cured.

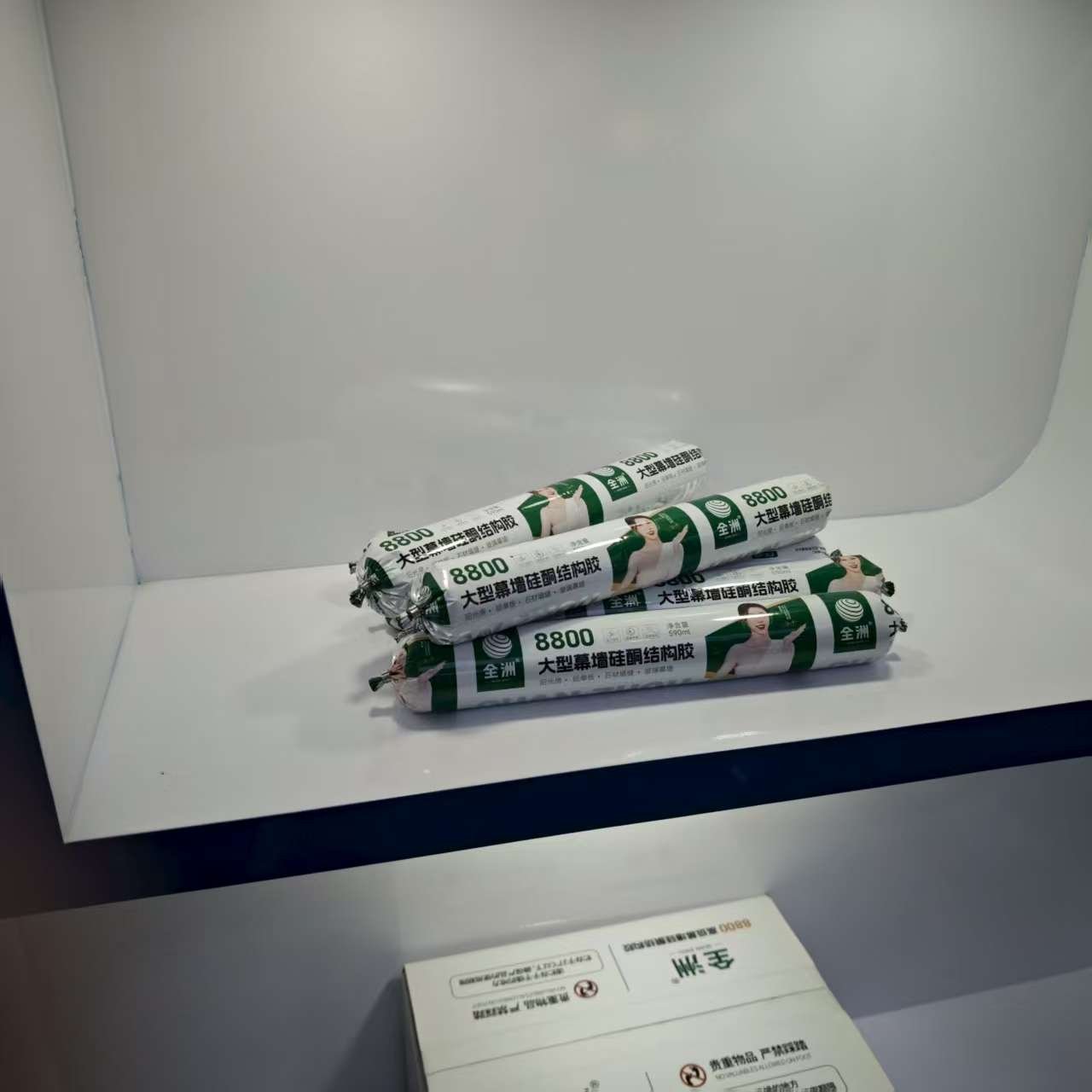

Q3: Can your silicone be used for structural glazing (bonding glass to frames)?

A: Yes, but you must use the correct grade. We supply High-Modulus Neutral Cure Silicones specifically formulated and tested for structural glazing applications. These products meet stringent international standards (like ETAG 002) for strength and durability. Do not use standard weatherproofing sealants for structural bonding. Consult us for the proper structural product data sheet.

Q4: What surfaces/substrates does it adhere to? Do I need a primer?

A: Our silicones adhere well to most common building materials: glass, aluminum, ceramics, painted metals, many plastics, and cured wood. Adhesion to porous surfaces (concrete, bare wood, some stones) may be variable and often requires a specific silicone primer to ensure a strong, lasting bond. We can advise on primer selection.

Q5: What is the service temperature range? Can it be used outdoors or in cold storage?

A: Our standard silicones have an excellent service range of -50°C to +150°C, with intermittent peaks to 200°C possible. This makes them perfectly suitable for extreme outdoor weathering, as well as sealing joints in cold rooms, freezers, and around ovens/fireplaces. They remain flexible and do not become brittle in the cold.

Q6: How should it be stored, and what is the shelf life?

A: Store unopened cartridges in a cool, dry place (below 27°C/80°F), away from direct sunlight and frost. The typical shelf life is 12-15 months from the date of manufacture, printed on the cartridge. Once opened, use the product promptly.

Q7: What support do you offer for large project specifications?

A: For engineering and large-scale projects, we provide:

Product Selection Guidance: Help choose the right silicone for specific substrates and performance requirements.