FAQ

Q1: What exactly is a Wood Veneer WPC Panel? How does it differ from solid wood panels or printed WPC panels?

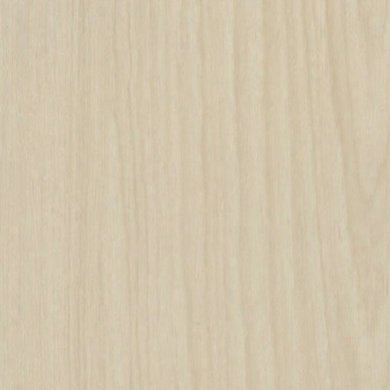

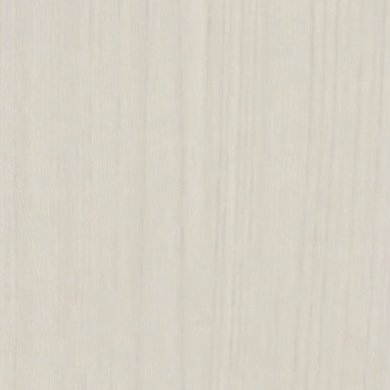

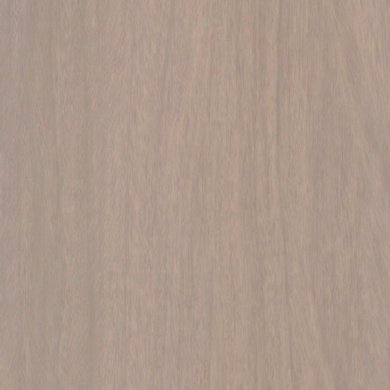

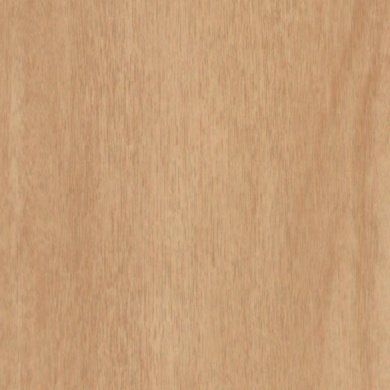

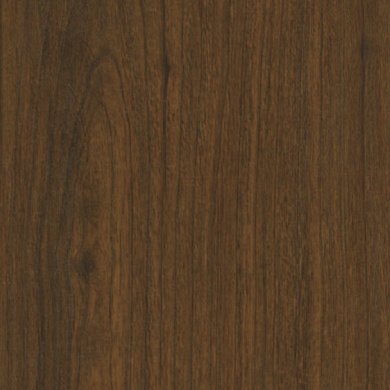

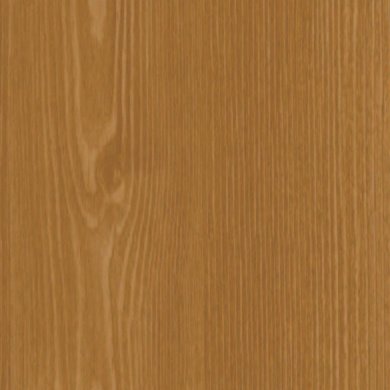

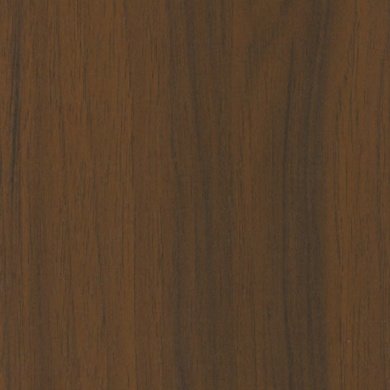

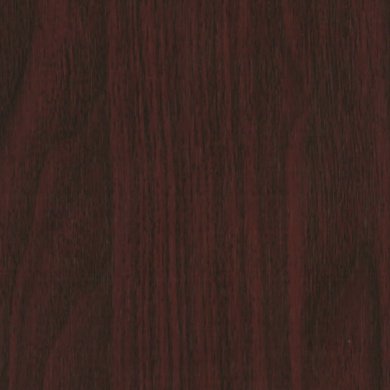

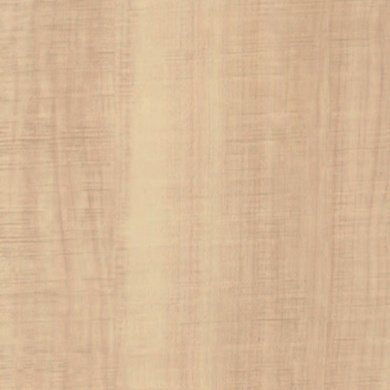

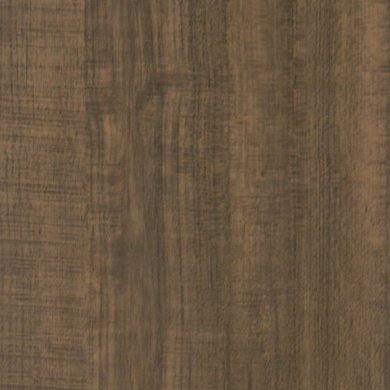

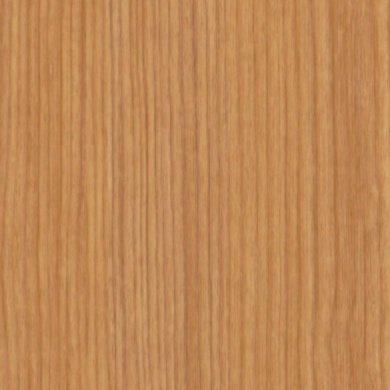

A: Our Wood Veneer WPC Panel consists of a high-stability, moisture-resistant Wood Plastic Composite core, topped with a genuine. Unlike solid wood, it won’t warp or crack due to humidity changes. Compared to printed WPC panels with photographic finishes, it offers the authentic, unique texture, depth, and feel of real wood, with each panel having natural grain variations.

Q2: What are the main advantages over traditional wood wall cladding?

A: The key advantages are:

Dimensional Stability: The WPC core prevents expansion, contraction, warping, and cracking, making it ideal for environments where solid wood would fail.

Low Maintenance: The factory-applied UV lacquer or oil finish is durable and requires no sanding or refinishing. Simple dusting or damp wiping is sufficient.

Faster, Cleaner Installation: The panelized system with a hidden clip method allows for dry, quick installation over battens, minimizing on-site mess and labor time.

Consistent Quality: Provides the beauty of wood without the knots, splits, or inconsistencies often found in lower-grade solid wood planks.

Q3: Where is the wood veneer sourced from? Is it sustainable?

A: We source veneers from reputable, managed suppliers. For projects requiring verified sustainability, we strongly recommend and can supply panels with FSC (Forest Stewardship Council) certified veneer, providing a full Chain of Custody. This is a critical requirement for many green building projects (like LEED).

Q4: How durable is the wood surface? Can it scratch or stain?

A: The surface is protected by a high-performance UV-cured lacquer or hard-wax oil finish, providing excellent resistance to scratches, stains, and everyday wear. Its abrasion resistance (≥400 rpm on the Taber test) is suitable for most interior wall applications. We recommend treating it with the same care as high-quality furniture—using coasters and avoiding sharp impacts.

Q5: Can the panels be used in humid areas like bathrooms or kitchens?

A: While the WPC core itself is highly moisture-resistant, the real wood veneer surface, even with protection, is a natural material. We recommend it for bathroom dry zones (e.g., feature walls away from direct shower spray) and kitchen accents. It is not suitable for saunas, steam rooms, or areas with constant water immersion. Good ventilation is always advised.

Q6: What is the lead time for custom projects (specific species, color, size)?

A: For custom orders (species, stain color, non-standard size/thickness), the typical lead time is 25-35 working days after final approval of all details and receipt of deposit. We will provide a precise timeline with your formal quotation. Standard items have a shorter lead time.

Q7: How do we maintain and clean the panels?

A: Maintenance is simple:

Regular Cleaning: Dust with a soft, dry, or slightly damp cloth.

Stain Removal: Use a mild, pH-neutral soap solution. Wipe dry immediately.

Avoid: Harsh chemical cleaners, abrasive pads, or steam cleaners, as they can damage the protective finish.

Q8: What is the MOQ for custom orders?

A: The Minimum Order Quantity for custom specifications (e.g., a unique stain color or specific size) typically starts at one 40-foot High Cube container. For smaller custom requests, please consult with our project team, as we may accommodate them depending on the scope.