FAQ

Q1: What is the main difference between indoor and outdoor WPC panels?

A: Outdoor WPC panels are engineered for extreme weather. They have a higher polymer content, advanced UV stabilizers, and anti-fungal additives. They are also thicker, often have a hollow multi-chamber structure for strength and drainage, and use a co-extrusion or full-cap layer for superior, long-lasting color retention, unlike surface-printed indoor panels.

Q2: How long will the color last without fading?

A: Our panels undergo accelerated QUV testing. The co-extruded color layer ensures a colorfastness rating of ≥7-8 after 1500+ hours of testing, which translates to 15-20 years of minimal, acceptable fade under normal outdoor conditions.

Q3: Can these panels withstand freezing temperatures and direct sunlight?

A: Yes. The material formulation has a wide operational temperature range (typically -40°C to +70°C). It is highly resistant to thermal expansion/contraction, freeze-thaw cycles, and UV degradation, making it suitable for almost all global climates.

Q4: Is maintenance required?

A: Maintenance is minimal. Unlike wood, it never needs painting, staining, or sealing. Routine cleaning with water, a mild soap, and a soft brush is sufficient to remove dirt, pollen, or mildew, keeping its appearance like new for years.

Q5: Can panels be cut and worked with standard tools?

A: Yes. They can be easily cut, drilled, and shaped using standard woodworking tools (saw, drill). We recommend carbide-tipped blades for the cleanest cuts. Always follow standard safety procedures.

Q6: What is the MOQ and lead time?

A: Standard color and profile MOQ is one 40-foot container. For custom colors or profiles, MOQ is negotiable based on project scale. Production lead time is typically 25-30 working days after order confirmation for standard items.

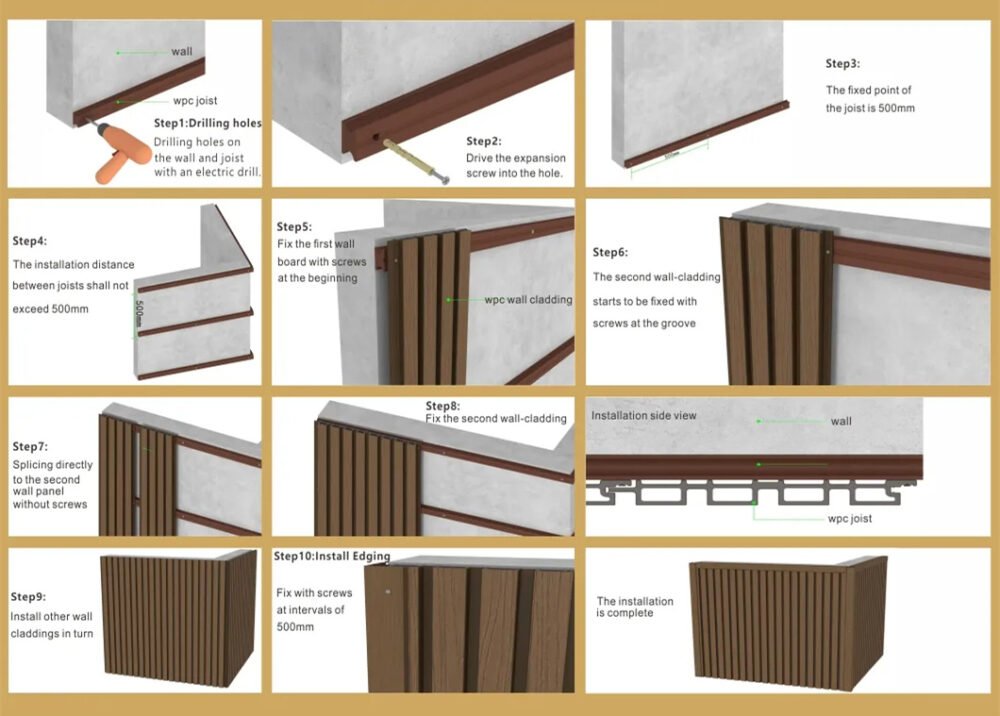

Q7: Do you provide a complete installation system and accessories?

A: Absolutely. We supply a complete system including aluminum/stainless steel hidden clips, starter/ender trims, corner profiles (inside & outside), J-channels, and end caps. We also provide detailed CAD installation drawings and guides.