FAQ

Q1: What is PU Stone, and how does it differ from real stone or lightweight cement panels?

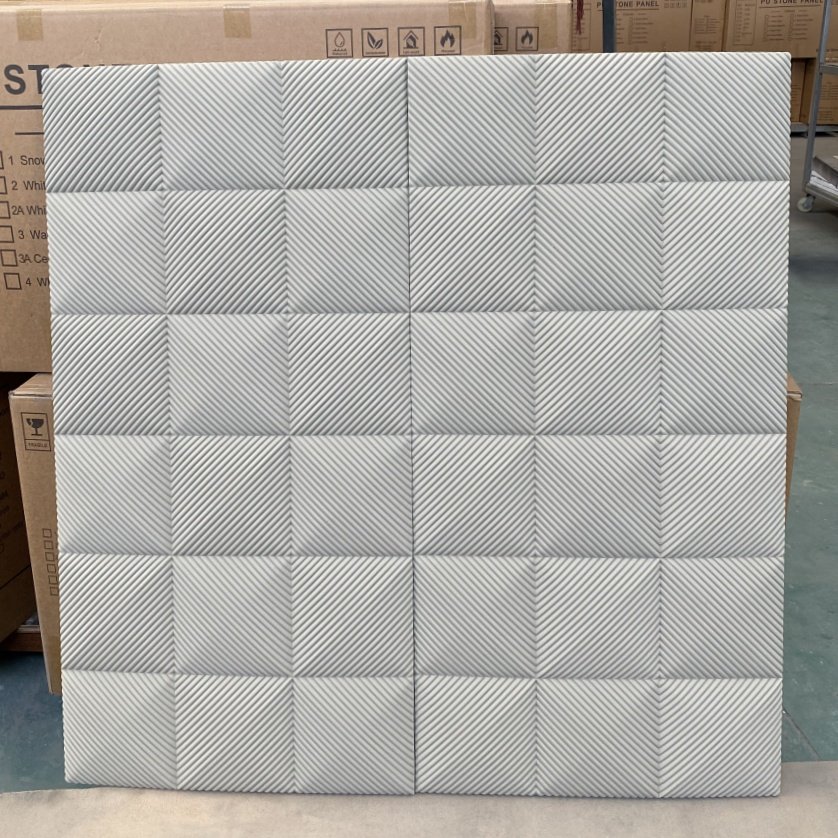

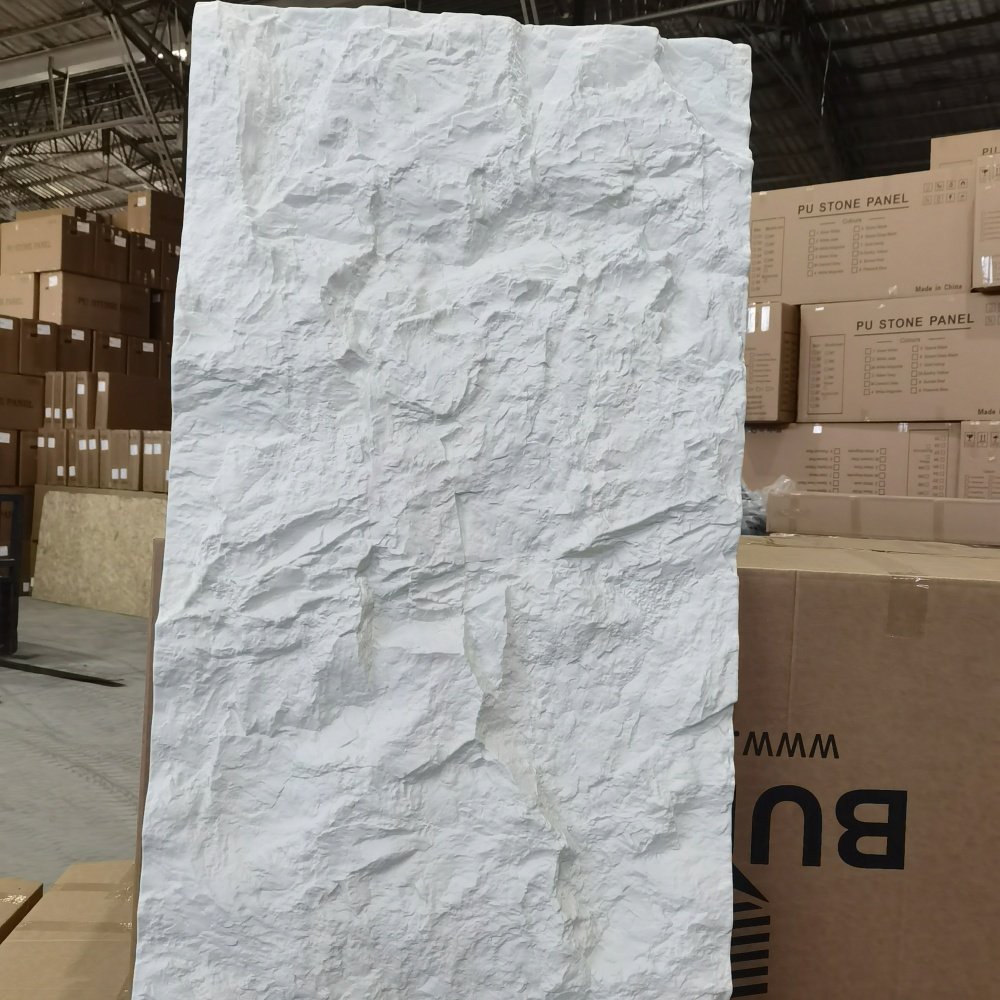

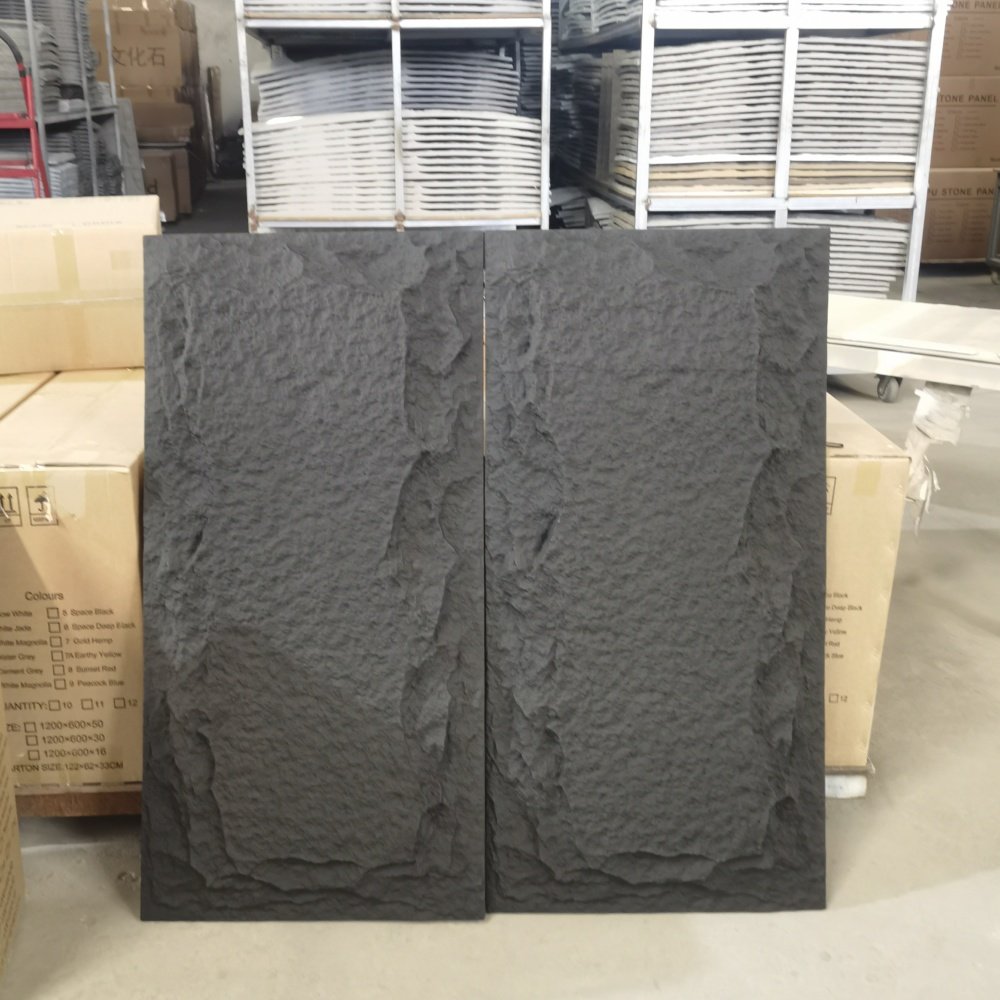

A: PU (Polyurethane) Stone is a high-density, rigid synthetic material molded to perfectly replicate the texture and appearance of natural stone. Compared to real stone, it’s approximately 90% lighter, significantly easier to install, and offers better insulation. Unlike lightweight cement panels, PU is more flexible (less prone to cracking), has finer detail reproduction, and is inherently waterproof.

Q2: Is it suitable for both interior and exterior applications?

A: Yes, but with correct specification.

Interior: Perfect for all interior feature walls, columns, and ceilings.

Exterior: Can be used for façade cladding, garden features, and trims only if an exterior-grade PU formulation and a dedicated UV-resistant exterior coating system are specified and correctly applied. Please consult our technical team for exterior project details.

Q3: How is it installed? Is structural reinforcement needed?

A: Installation is straightforward due to its light weight. The standard method is direct adhesion using a high-strength construction adhesive (specific for PU materials) to a solid, prepared substrate. Mechanical fixing with screws is recommended for large panels or exterior applications. No additional structural reinforcement is needed for the panel itself, as it places minimal load on the building.

Q4: Can it be painted or customized?

A: Absolutely. Most products are supplied primed and ready for painting with standard acrylic or masonry paints, allowing for unlimited color matching. We also offer factory-applied custom finishes, including realistic multi-layer stone effects, matte/flat finishes, or specific RAL color matches for project consistency.

Q5: How durable is it? Will it crack, fade, or yellow?

A: PU Stone is highly durable. It is impact-resistant, moisture-proof, and will not crack like gypsum or natural stone. For interior use with standard finishes, fading and yellowing are minimal. For exterior use, the specialized coating system is designed for long-term UV and color stability, backed by a comprehensive warranty.

Q6: Do you offer custom designs and molds?

A: Yes, customization is our strength. We can create custom molds from your provided samples, drawings, or 3D models for unique profiles, patterns, or logos. This service is ideal for branding, heritage restoration, or creating signature architectural elements. A mold development fee and project MOQ apply.