FAQ

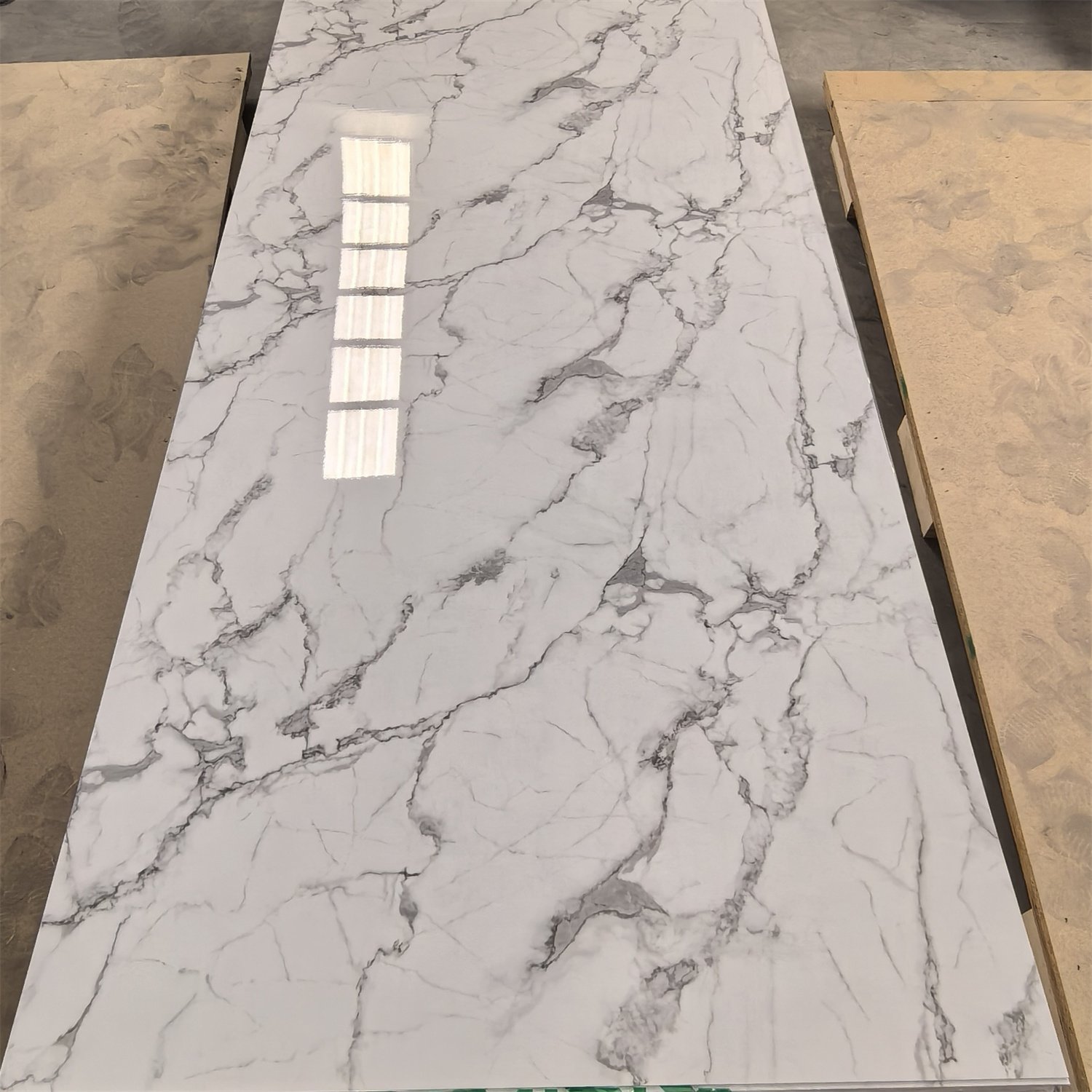

Q1: What is PVC Marble Sheet, and how does it compare to real marble or acrylic sheets?

A: It’s a rigid decorative panel with a high-fidelity printed marble surface and a protective wear layer. Compared to real marble, it’s 90% lighter, 100% waterproof, and requires zero sealing or polishing. Unlike acrylic sheets, it is more cost-effective, has better fire resistance, and is less prone to scratching.

Q2: Is it suitable for wet areas like bathrooms and kitchens?

A: Yes, absolutely. The material is completely non-porous and waterproof, making it an ideal, low-maintenance choice for shower surrounds, kitchen splashbacks, and bathroom vanities where moisture resistance is critical.

Q3: How is it installed?

A: Primary methods are:

Direct Adhesion: Using high-strength contact adhesive onto a flat, solid substrate (plywood, MDF, plasterboard).

Dry-Hanging/Framing: Using an aluminum frame system for a seamless, panelized look on walls or ceilings.

We provide installation guides and can advise on the best method for your project.

Q4: Can it be used for curved surfaces or custom shapes?

A: Yes. A key advantage is its excellent cold-forming capability. It can be bent to create curved columns, arched ceilings, or rounded edges. It can also be easily cut, routed, and CNC machined for intricate designs.

Q5: How durable is the surface against scratches and stains?

A: The surface is protected by a hard, transparent wear layer that offers good resistance to scratches from everyday use and makes it highly stain-resistant. Common household stains can be wiped clean with a damp cloth.

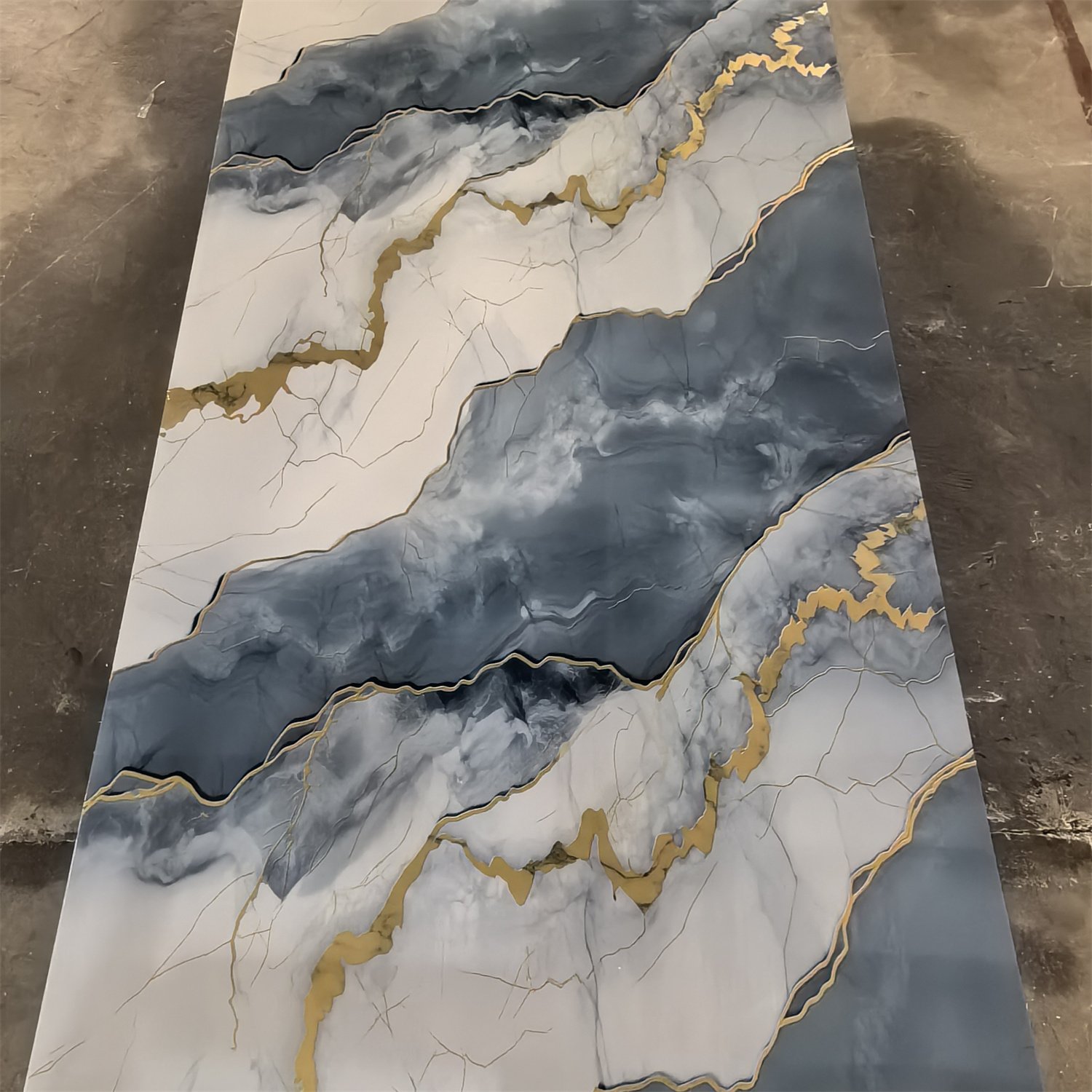

Q6: Do you offer custom patterns, sizes, and finishes?

A: Yes. We specialize in customization for project volumes.

Q7: What is the MOQ and lead time?

A: Standard product MOQ is one 20ft container. For custom designs, MOQ is negotiable based on complexity. Production lead time is typically 18-25 working days.