FAQ

Q1: What is a sandwich panel? What is its core structure?

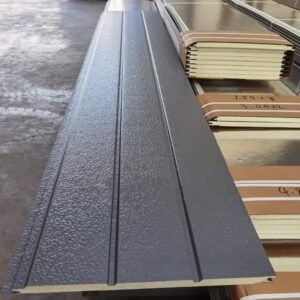

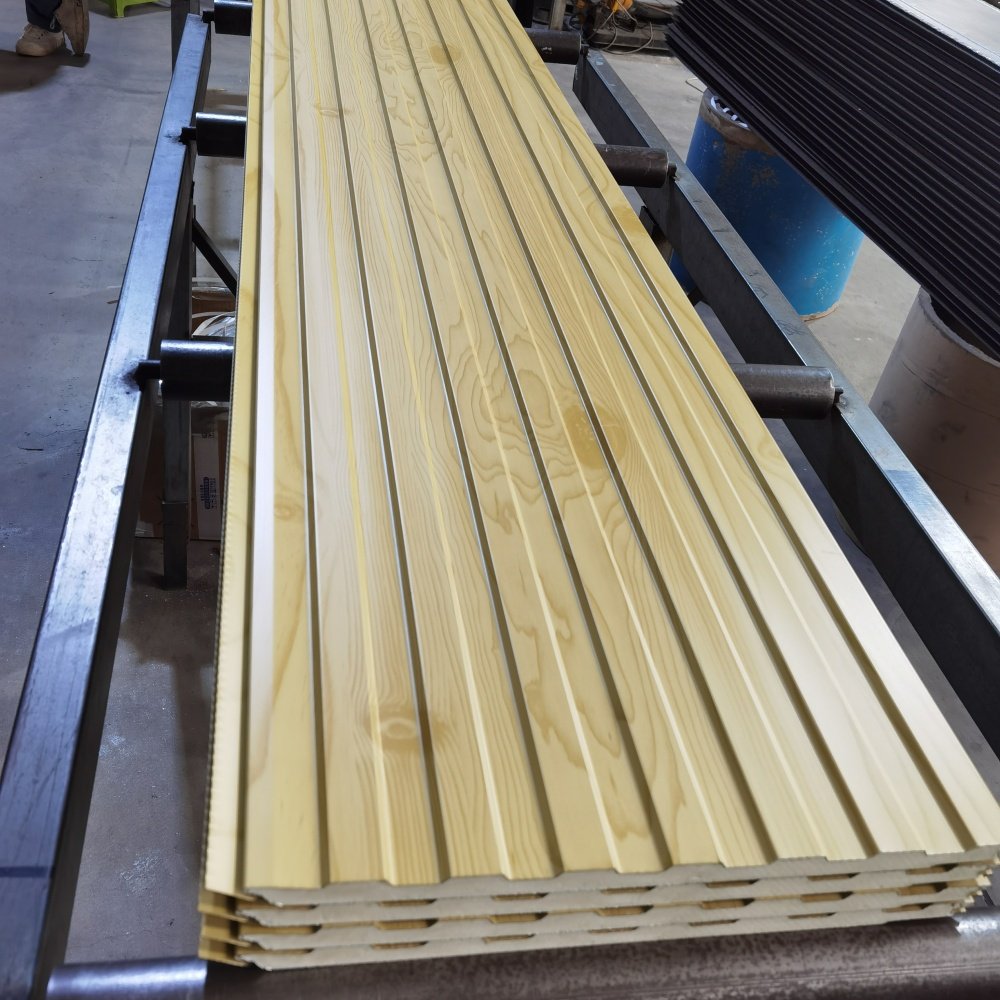

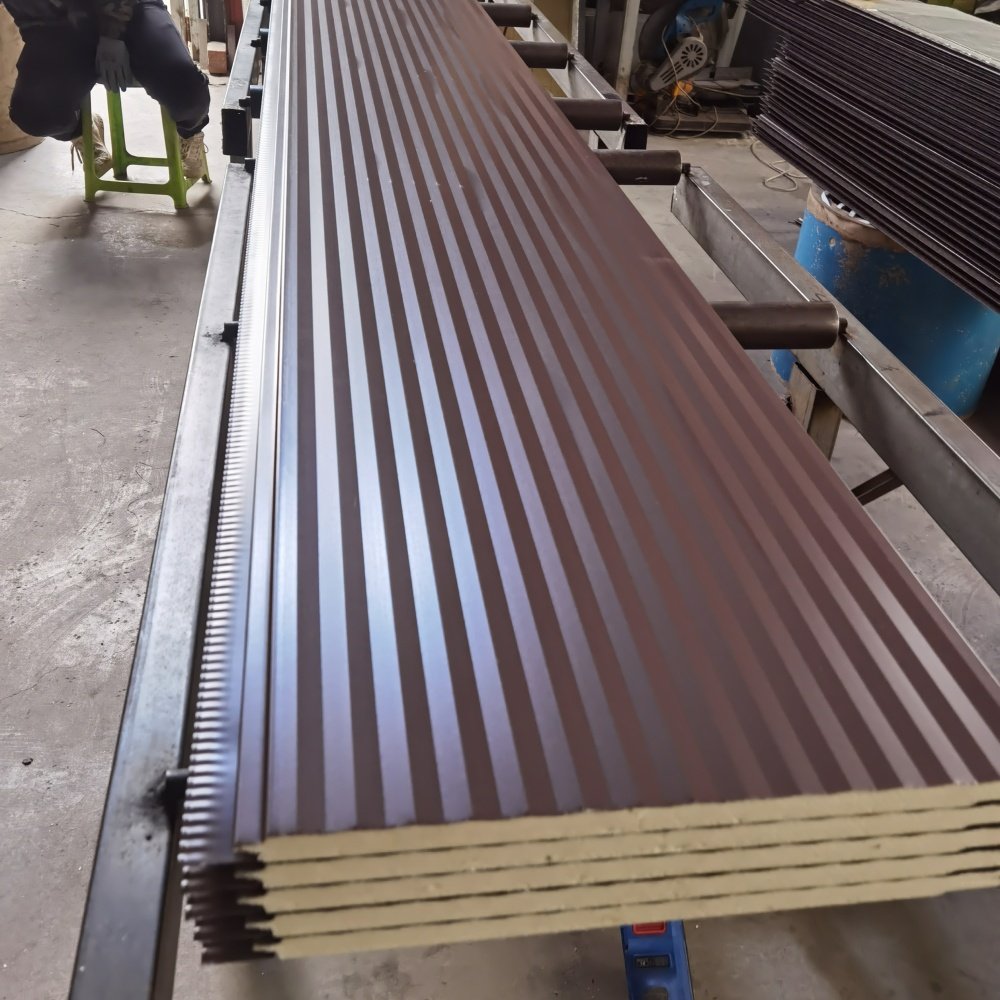

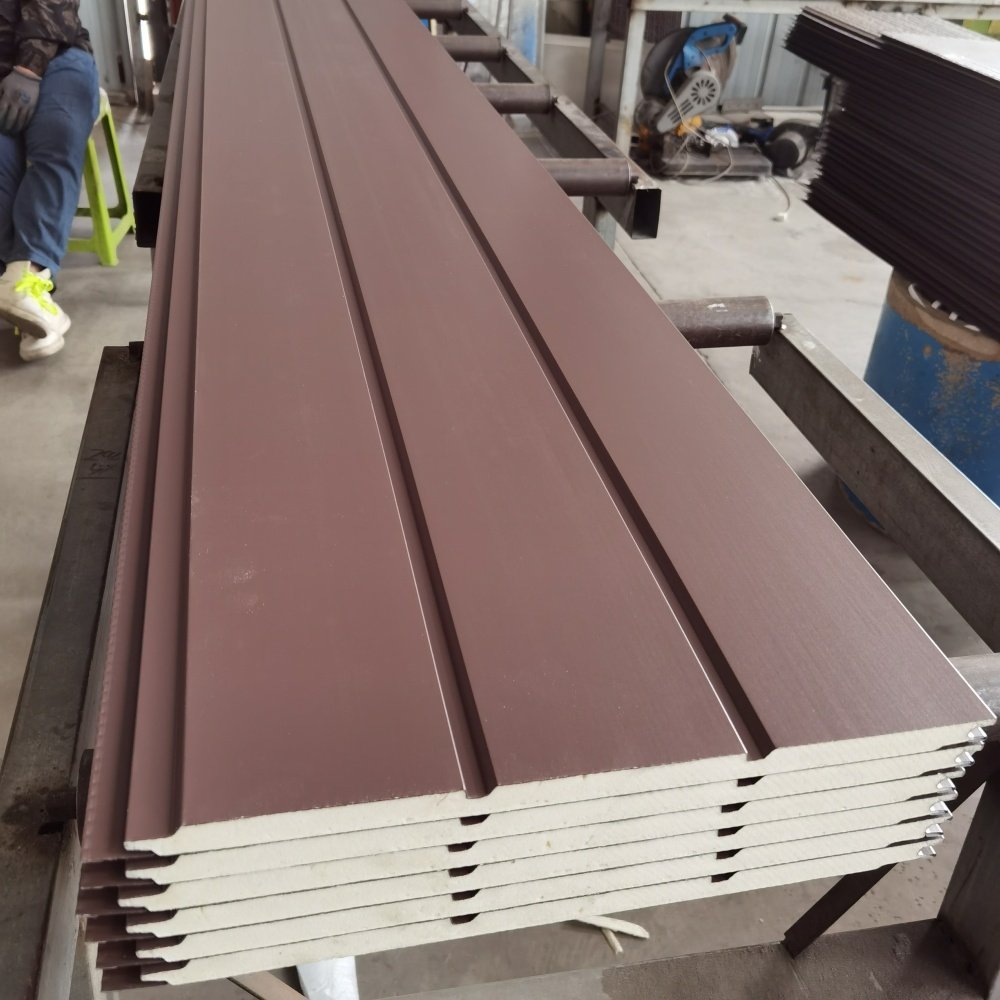

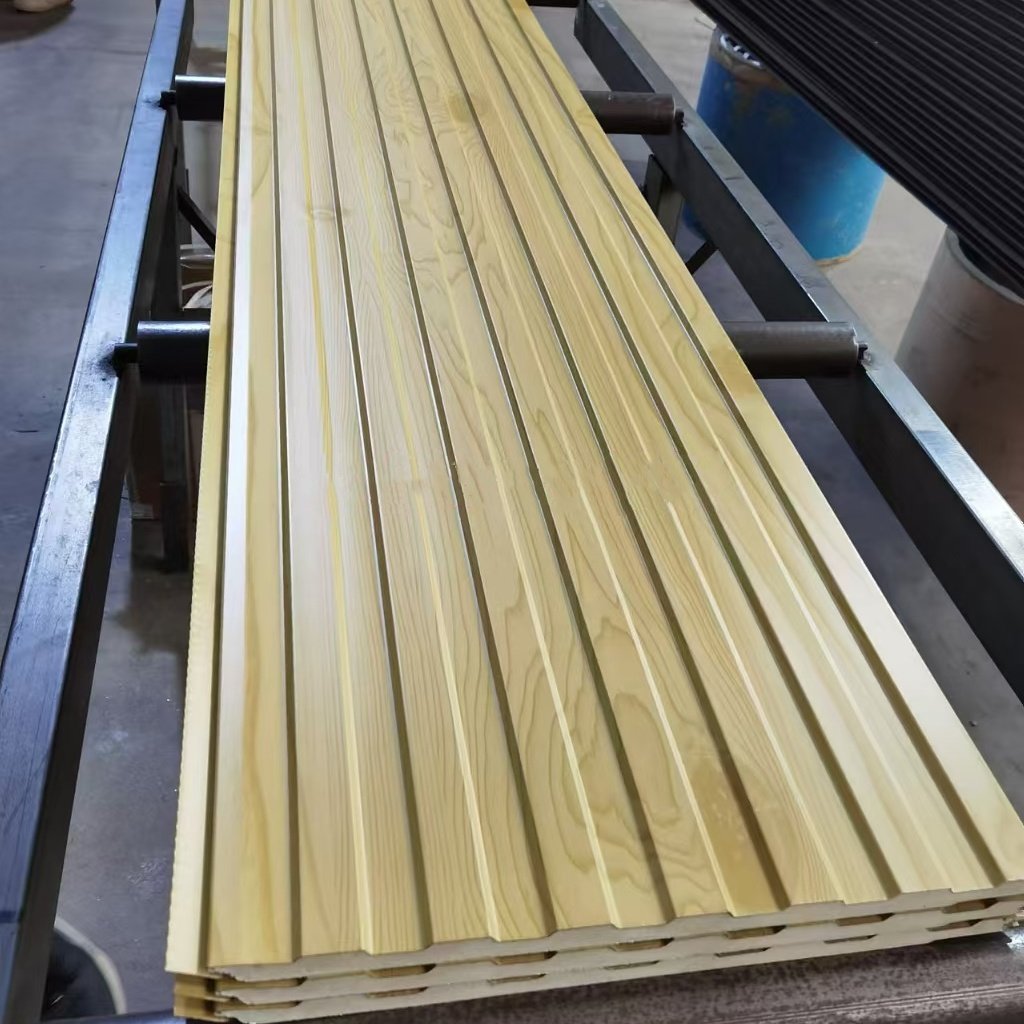

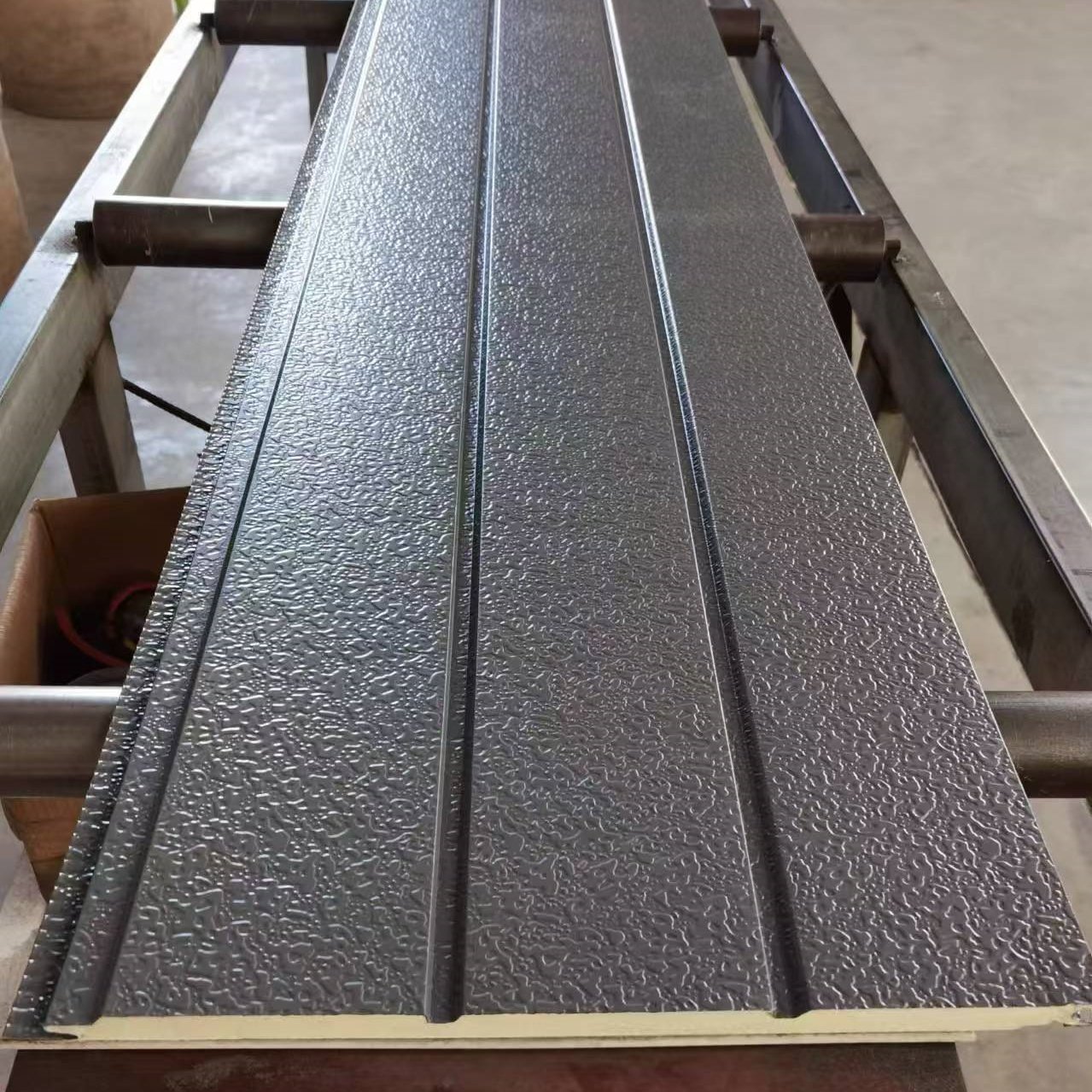

A: Sandwich panels (also known as composite panels or insulation panels) are a “sandwich” structured building envelope material. They are composed of two layers of metal facing materials (such as color-coated steel sheets or aluminum sheets) and a continuous insulating core material in between, all bonded together with high-strength adhesive in a single process. They integrate load-bearing, thermal insulation, heat insulation, and decorative functions.

Q2: Is installation quick and easy?

A: Yes, this is one of the core advantages of sandwich panels. They use a dry construction method, connected by hidden clips or exposed fasteners. The installation speed is several times faster than traditional masonry or on-site composite walls, significantly shortening construction time and reducing labor costs. We provide detailed installation diagrams and guidance.

Q3: How is the thermal insulation performance of sandwich panels measured?

A: It is mainly measured by thermal conductivity and heat transfer coefficient.

Thermal conductivity: The insulation capacity of the core material itself; a lower value is better.

Heat transfer coefficient: The overall thermal insulation performance of the entire panel at a specific thickness.

Q4: What types of buildings are they suitable for?

A: They have a wide range of applications, mainly including:

Industrial buildings: Factories, warehouses, logistics centers.

Commercial buildings: Supermarkets, shopping malls, stadiums, exhibition halls.

Special buildings: Cold storage, clean rooms, explosion-proof workshops (requiring special design).

Agricultural buildings: Livestock farms, agricultural product processing workshops.

Q5: Are maintenance costs high?

A: Maintenance costs are extremely low. The high-quality surface has excellent corrosion resistance, UV resistance, and self-cleaning properties, usually requiring only rainwater to maintain its appearance. The structure is durable and does not require regular maintenance like traditional walls.

Q6: As a buyer, what are the MOQ and delivery time?

A: The minimum order quantity for standard products and colors is usually one 20-foot container. The MOQ for custom colors or special specifications will be higher. The production cycle from order confirmation to factory shipment is usually 15-25 working days, depending on the total order quantity and complexity.